I have been building model kits for around 50 years, and have worked as a professional model-maker (scratch-building, not kits) for at least 30 years. So I didn't expect to get much for myself out of this book. I was just interested to see how useful the book was for novice model-kit builders.

I picked up Airfix Model World Basic Guide to Modelling by Stu Fone expecting a fairly simple book with tips for the absolute beginner. However, as well as the beginner's information there are plenty of tips and tricks for the more experienced modeller.

The book is a collection of articles reprinted from the Airfix Model World magazine. However, it is put together so that each article takes the modeller one step further through the model-building process.

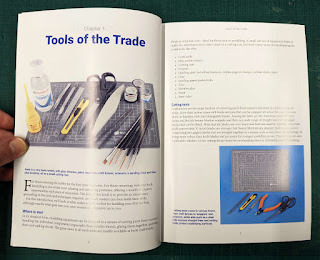

From Tools, through basic assembly, clean up and filling and on to painting, applying water side transfers (decals), varnishing and aftermarket accessories. There is also a chapter on scratch-building replacement parts, either for lost parts or to improve the original kit.

Each chapter is simple enough for beginners to find useful but also features tips from the author's years of experience that even as a veteran model maker often proved useful.

As a professional model-maker, I don't build that many plastic model kits these days. So some of the tips in the book, which clearly come from years of kit building, were very interesting and I will certainly refer back to the book when putting plastic kits together in the future.

Seeing how others paint models is always useful, so discovering the author's painting processes was good and very interesting, especially his weathering techniques.

As for applying decals, I have used a softener a few times and found it certainly helps disguise the transfer and avoid creases. However, I will be trying some of the products mentioned in the book, to see if I prefer them.

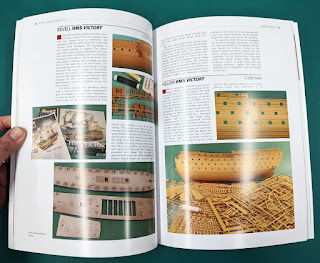

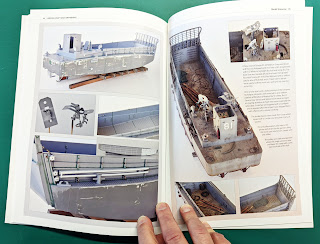

As I mentioned above, the book features a chapter on scratch-building parts for kit models. Now, this is an area that I really enjoy, as a lot of my models are entirely scratch-built. It is good to see that this is being promoted to beginner model-makers, as it can be the most satisfying part of the process, and shouldn't be too difficult if approached with an open mind.

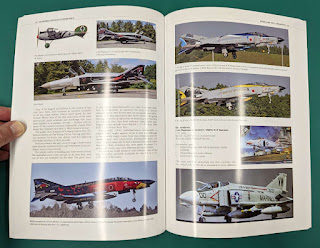

One of the aspects of this book that caught me somewhat by surprise is the fact that not all of the model kits and other modelling products in the book are manufactured by Airfix (or Humbrol). There is an open attitude to discussing other manufacturers' kits etc.

An excellent book that I may well keep in my collection (or possibly pass on to a more inexperienced modeller).

Pick up the book HERE.